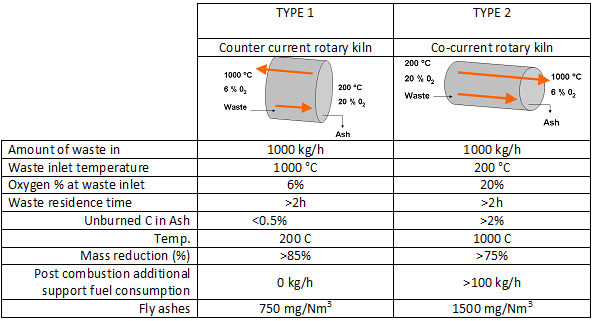

Waste incineration in rotary kiln is considered to be Best Available Technology (BAT) for medical and hazardous waste treatment, because of continuous operation creating steady state conditions, ensuring complete combustion which leads to complete destruction of dioxins and furans. Based on the flow of solids compared to the gases in the kiln, the kilns can be either co-current or counter-current rotary kiln.

Counter-Current Rotary Kilns

In counter-current rotary kilns, flue gases flow in the opposite direction of the waste, against the inclination of the kiln. Solids move by the rotary motion and by gravity from the high end to the low end of the kiln.

Incoming combustion air is cold (ambient) and contains max. oxygen level (21%). While flowing to the front of the kiln, the air heats up and gradually loses its oxygen to the combustion of the solids – basically becoming flue gas – so that at the front of the kiln the exiting gases contain little oxygen (6%) and is hot (1000 deg.C).

Incoming waste (solids) is cold and hits the front zone of the kiln where the atmosphere is low in oxygen and high in temperature. This vaporizes the volatiles in the solids in the entry zone itself. This creates a hot, rich gas in an oxygen-poor atmosphere at the entry to the post combustion zone.

At this point, blend secondary air in to start the gas phase combustion (post combustion) and increase the temperature of the gases from 1000 deg. C to 1200 deg. C without the need for support fuel.

The incoming combustion air and oxygen-rich atmosphere cool down the exiting wastes (ashes) and ensure a perfect burn-out.

Additional features are that this type of kiln ensures better turbulence and hence can be kept short and compact. In order to achieve the same residence time for the solids, the rotation is slower the in a co-current kiln which in turn reduces fly-ash carry over.

Co-Current Rotary Kilns

In co-current rotary kilns, flue gases flow in the same direction of the waste, with the inclination of the kiln. Solids move by the rotary motion and by gravity from the high end to the low end of the kiln.

Incoming combustion air is cold (ambient) and contains max. oxygen level (21%). While flowing to the back of the kiln, the air heats up and gradually loses its oxygen to the combustion of the solids – basically becoming flue gas – so that at the back of the kiln the exiting gases contain little oxygen (6%) and is hot (1000 deg.C).

Incoming waste (solids) is cold and hits the front zone of the kiln where the atmosphere is high in oxygen and low in temperature. This makes support fuel necessary to light up the incoming waste.

At the back (low end) of the kiln, the solids no longer contain volatiles. So support fuel heats the gases flowing to the post-combustion zone, from 1000 deg. C to 1200 deg. C.

The incoming combustion air and oxygen-poor atmosphere do not effectively cool down the exiting wastes (ashes) for a good burn-out. The high temperature in the ash evacuation zone (1000 deg. C) creates a high risk of slagging and makes ash handling difficult.

Additional features are that this type of kiln ensures little turbulence and hence the kiln must be longer. To keep the combustion going, kiln rotation must be faster than in a counter-current kiln, leading to more fly-ash carry over.

Manufacturing of Counter- and Co-Current Rotary Kilns

The main difficulty with the counter-current kiln is the temperature gradient across the fire door which seals off the waste hopper (ambient temp.) from the kiln entry (1000 deg. C).This requires specially engineered designs and a lot of experience to make the fire door reliable and long-lasting.

This is the main reason why the counter-current kiln is not more wide-spread.