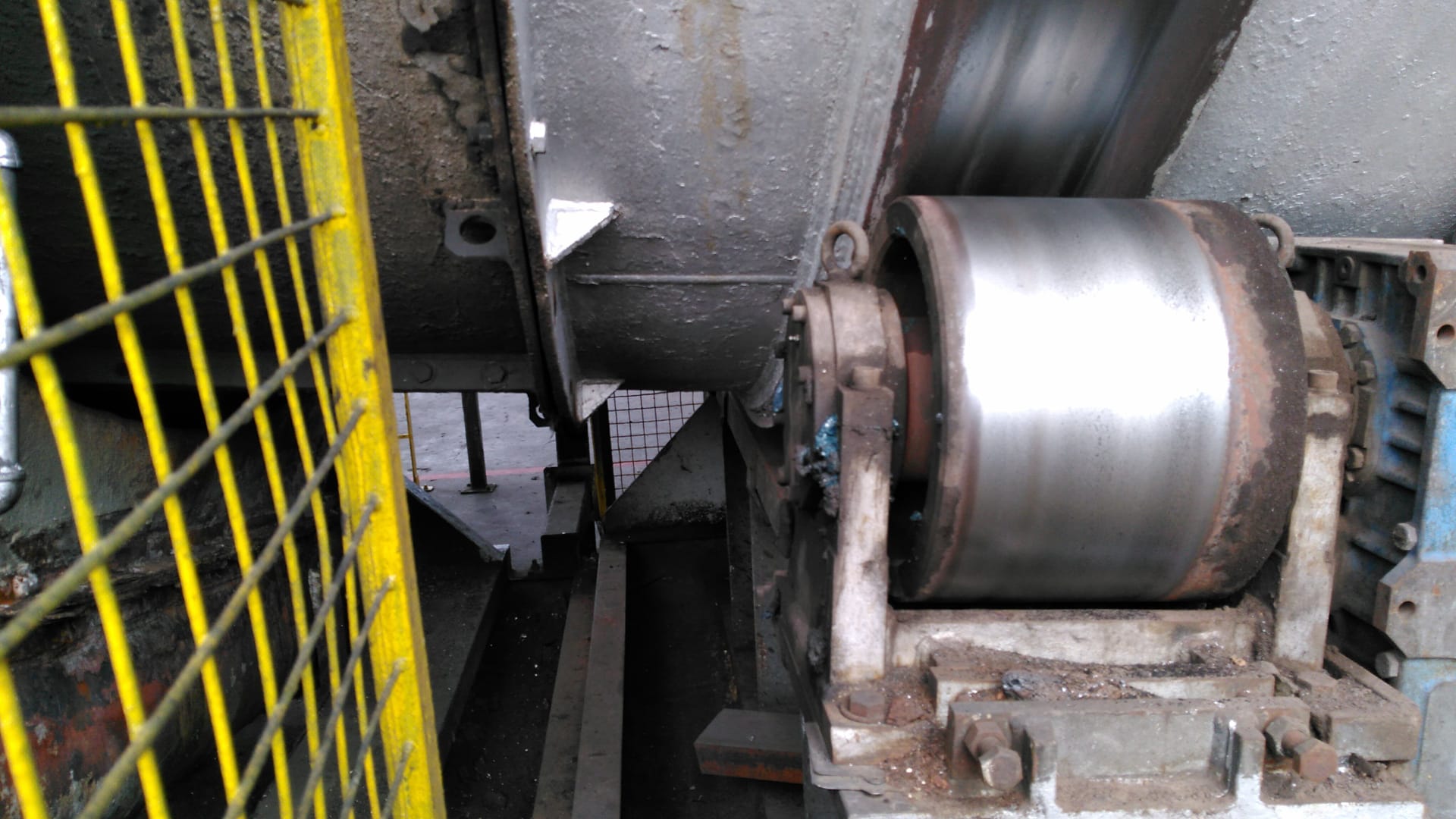

BIC Group specializes in providing tailored consultation services for rotary kiln incinerators, drawing on our extensive engineering and operational expertise. Our focus is on assessing, maintaining, repairing, and upgrading existing facilities to optimize productivity and extend their lifespan with minimal intervention. Clients trust us for expert guidance in enhancing the performance and sustainability of their rotary kiln facilities.

One common issue we address is kiln alignment problems, often encountered in dated kilns. Our team excels in diagnosing and resolving alignment issues, ensuring precise alignment to facilitate smooth operations and prevent disruptions.

Another challenge we tackle is slagging from fly ash melting. This can lead to frequent shutdowns, reducing plant availability and revenue. Our innovative solutions minimize shutdown time and eliminate the need for specialized contractors, thereby optimizing efficiency and profitability.

Choking of ducts, heat exchangers, and baghouses is yet another issue plaguing many incinerators. BIC Group is adept at diagnosing the root causes of such issues and implementing cost-effective solutions to prevent downtime and maintain efficient operation.

Moreover, we offer expertise in upgrading automation systems, incorporating the latest sensors and technologies. By enhancing monitoring and diagnostic systems without overhauling the entire plant, we improve efficiency and productivity while maximizing operational longevity.

Clients can rely on BIC Group for comprehensive evaluations and strategic recommendations tailored to their specific needs. Contact us today for a consultation on how we can help optimize the performance and sustainability of your rotary kiln facilities.